Three ILLINOIS students won the Judges Choice global innovation award with novel coating process to decrease greenhouse gas emissions from power plants. Shell Ideas360.

The Illinois team is one of five teams and the only team from the United States. As winners they received the Shell Ideas360 trophy and a National Geographic adventure of a lifetime.

The competition awards innovation surrounding the world’s water supply, food and energy issues. The students will receive real-life experiences that make an impact on the world.

Somak Ghosh and Antonio Woods, both ECE undergraduate students, and Chemistry student Sean Ebihara have been working on their idea titled “Graphene Coated Condensers for a Greener Future.” The idea looks at the Graphene coating process to reduce greenhouse gas emissions and the footprint of power plants.

“There has been a distinct lack of innovation in power plants, with the last one built in the United States in the late 1970s,” Ghosh said on the Shell360 website. "Crucially our idea is also technologically and financially sound and it’s awesome that our idea has been recognized (sic) through the Shell Ideas360 competition – it’s a validation of all the hard work we’ve put into it."

The other finalists include The SeaShrooms Project from the Singapore Management University, Team REPiphany from the Nanyang Technological University in Singapore, Tri-gen from the University of Cambridge in the United Kingdom, and GrowSmart from the Indian Institute of Technology, Kharagpur in India.

The competition began by 982 teams submitting ideas for projects. From there, only 74 teams moved on to Stage II from where the final five teams were chosen. Chosen May 23, the final five teams began turning their ideas into in-depth proposals. They will also receive three days of intensive coaching before presenting to Shell executives, innovators and industry leaders.

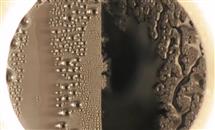

As the team explained in their pitch video, 'Because graphene (shown on the left half of the image) is ultra-thin and intrinsically condensation-phobic, it experiences dropwise mode condensation...This type of condensation allows for heat transfer, up to an order of magnitude better than uncoated pipe, thus making the condenser and power plant operate more efficiently.

As the team explained in their pitch video, 'Because graphene (shown on the left half of the image) is ultra-thin and intrinsically condensation-phobic, it experiences dropwise mode condensation...This type of condensation allows for heat transfer, up to an order of magnitude better than uncoated pipe, thus making the condenser and power plant operate more efficiently.